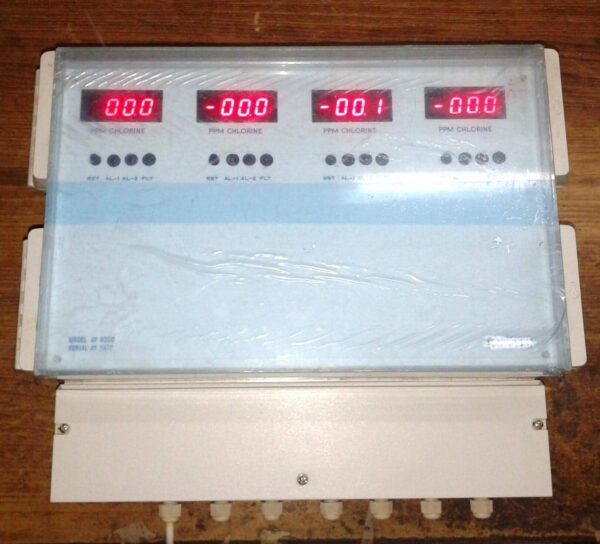

Four Sensor Gas Detector

Four Sensor Gas Detector

In Industrial Environments, exposure to oxidizing gases poses a significant risk to both personnel and equipment. Prolonged exposure to even low concentrations can reach harmful safety thresholds, while higher concentrations can severely impact respiratory health and corrode equipment, leading to expensive repairs.

The Four Sensor Gas Detector from Husaini® Engineers is a state-of-the-art safety device engineered to protect industrial environments from the dangers of gas leaks. Its real-time monitoring, customizable alarm settings, and integration capabilities make it indispensable for maintaining workplace safety and operational efficiency. By proactively detecting and mitigating gas hazards, this device offers peace of mind and compliance with safety standards.

How Does the Four-Sensor Gas Detector Enhance Safety?

Real-Time Monitoring:

- Each sensor continuously measures the concentration of specific gases and displays the real-time values independently, ensuring comprehensive air quality assessment.

Early Detection and Alarming:

- The detector is equipped with visual and audible alarms that activate when gas concentrations exceed pre-set thresholds.

- Pre-alarm and main alarm levels can be configured to provide graduated warnings, enabling timely corrective actions.

Versatile Application:

- Ideal for facilities where gases such as chlorine are generated, stored, or metered, including chlorination plants with separate metering and storage rooms.

Customizable Alarm Levels:

- Different sensors can be assigned varying alarm thresholds (e.g., 2 ppm for one area and 5 ppm for another), catering to specific site requirements.

Key Features of Four Sensor Gas Detector

- Individual Sensor Displays: Each sensor has a dedicated display for real-time gas concentration readings, offering a clear and immediate overview of the monitored environment.

- Independent Alarm Contacts: Digital potential-free contacts for each sensor allow separate configurations for Alarm-I and Alarm-II, enhancing operational flexibility.

- Linear Analog Output: Analog outputs (4-20 mA) are linear with the sensor’s measurement range, ensuring accurate data transmission for integration into centralized monitoring systems.

- Industrial Hooter Integration: A common industrial hooter can be configured to alert personnel for all sensors, simplifying the alarm management process.

Application

- Chlorination Plants: Monitoring gas leaks in chlorine generation, storage, and metering rooms. Configurable alarm levels for different zones to provide comprehensive coverage.

- Chemical Manufacturing Units: Detecting harmful oxidizing gases released during production processes.

- Pharmaceutical Facilities: Ensuring a safe environment by monitoring gases used in synthesis and processing.

- Water Treatment Plants: Monitoring chlorine or other disinfectant gases used in purification.

- Industrial Storage Areas: Continuous monitoring of gases in areas where cylinders or drums of chemicals are stored.

- HVAC and Ventilation Systems: Integration with air quality systems to ensure safe levels of oxidizing gases in confined spaces.

- Food Processing Facilities: Monitoring gases used in preservation or fumigation processes.

Seamless Integration with Ancillary Safety Systems

The Four-Sensor Gas Detector is not just a standalone safety tool—it integrates seamlessly with additional safety equipment to create a comprehensive hazard mitigation system:

- Alarm Horns: Audible alerts to notify personnel of dangerous gas levels.

- Exhaust Fans: Automatically activated to improve ventilation and disperse gases.

- Automatic Gas Shut-Off Valves: Stop gas flow to prevent escalation of leaks.

- Sprinkler Systems: Douse areas to control the spread of toxic substances.

- Air Scrubbers: Neutralize harmful gases for safer air quality.