There are various technologies for gas sensing. Depending on the application, people seek different levels of sensitivity – typically between ppth for general industrial detection or ppm level for more precise laboratory monitoring.

Sensors based on chemical principles have inherent weaknesses that include short lifetime and secondary pollution issues; electrical variations could provide the solution.

Environments often contain numerous gases which must be detected and monitored, however existing standard analytical techniques like GC/Mass and optical spectroscopie are both time consuming and expensive. Therefore, an affordable and faster gas detection system would be highly desirable.

Optic sensors using laser spectroscopy technology offer one such potential solution. However, the major challenge involves attaining optimal performance from these sensors in terms of repeatability, stability and sensitivity.

Optic gas sensors employ a gas cell consisting of an emitter and detector placed directly opposite each other, with light from both being filtered before coming in contact with gas molecules. There are different topologies of the cells available; such as resonant [49, non-resonant or multi-pass cells; many different gas sensing mechanisms can be utilized such as chemiluminescence, photoacoustic or thermal infrared detection – any or all may be utilized depending on user requirements – while performance can be increased through various means such as increasing emission intensity of emitter and using more sensitive or faster detectors; further reduced power consumption can reduce maintenance costs while increasing lifespan/maintenance costs considerably

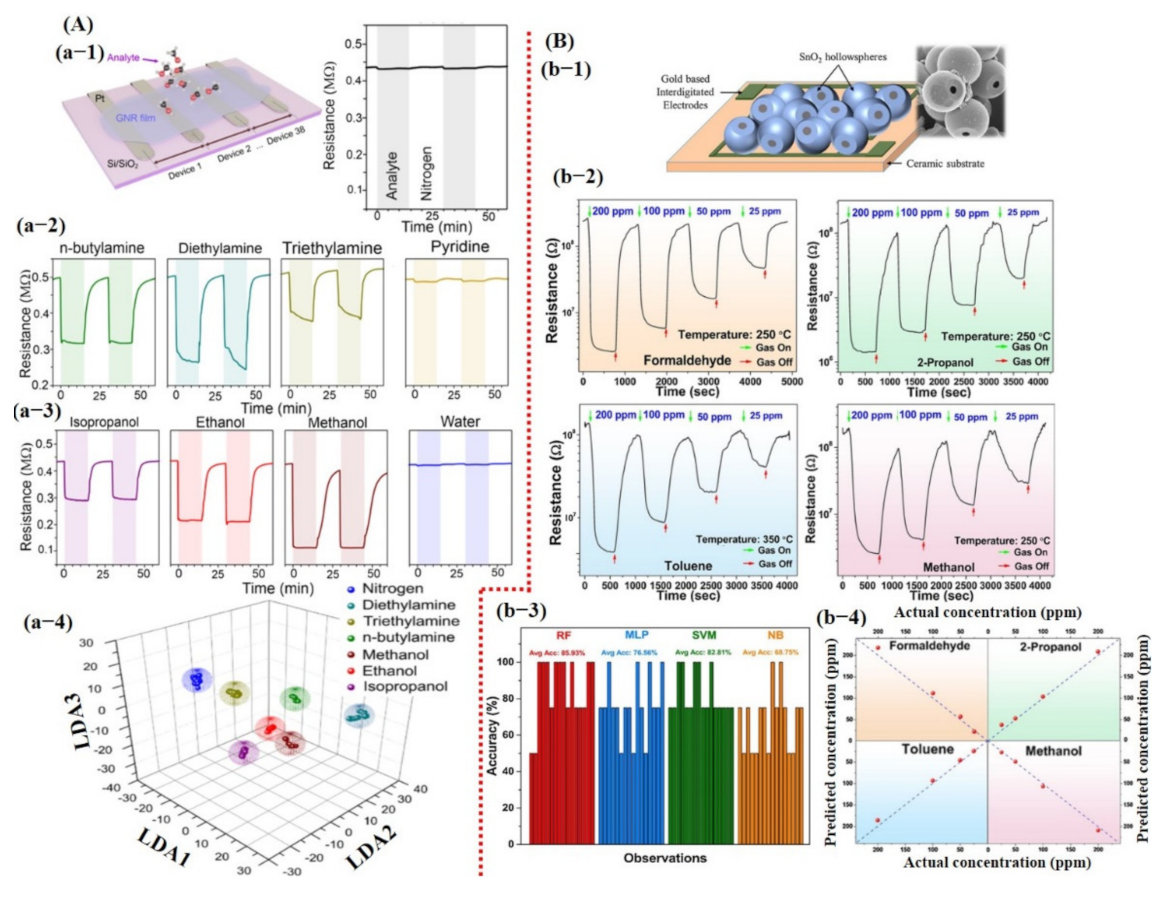

Metal oxide gas sensors are widely utilized throughout industry for an assortment of uses, from exhaust gas determination in vehicles to leakage detection at chemical plants and product quality assurance at food companies. Their basic operating principle relies on exposure to specific gases causing MOS materials’ valence band electrons to absorb them, leading to a decreased resistance which can then be measured electrically.

Selecting an optimal MOS material depends upon its bulk and surface properties as well as the nature and concentration of target gases, as well as morphological structure of MOS sensors which has a significant influence on their sensing properties. Different morphologies such as zero-dimensional, one-dimensional, and two-dimensional have been explored to improve gas sensing performance.

One-dimensional metal oxides with grains sizes comparable to two times Debye length provide superior conductivity responses due to the large surface area available for gas absorption. Other morphologies, including nanorods and heterojunctions, offer similar performance.

Carbon nanotubes possess a large volume-to-surface area ratio, high thermal and electrical conductivities, controllable topographies and can serve as an ideal platform for fabricating micro and nano devices.

Scientists from Technical University of Munich (TUM) have designed a gas sensor which uses solution-processed single-wall carbon nanotubes (SWCNTs) and dielectrophoretic stepwise deposition between carbon electrodes to detect nitric oxide gas.

Scientists demonstrated that exposure to nitrogen gas caused the electrical resistance of SWCNT mat to change. After removal from exposure, its resistance immediately returned back to its baseline resistance level.

The team also demonstrated how SWCNT gas sensors could be improved by functionalizing them with various materials, such as functionalizing them with sulfonated polyethylene dissolved in tetrahydrofuran for Cl2 detection and coating them with hydroxypropyl cellulose for HCl detection. These results demonstrated the enormous potential of modified SWCNTs as highly sensitive and selective gas sensors.

Conductive polymers such as polypyrrole (PPy), polyaniline (PANI) and polythiophene (PTh) have gained immense popularity for use as gas sensors due to their simple sensing mechanism, low cost and room temperature operation. Their wide p-electron conjugation enables easy modification of chemical structure and morphology for enhanced sensing performance; when exposed to gas molecules they change electrical transport properties resulting in increased or decreased resistance and conductivity which is then detected via readout circuitry.

Comparable to metal oxide sensors, carbon-photovoltaic (CP) sensors possess lower temperature dependence, faster response times and increased sensitivity. Unfortunately, their long-term stability remains an issue; being sensitive to humidity conditions they become degraded over time.

Husaini Engineers manufactures and supplies various gas sensors for different industries to detect gas leaks.